RAPIDAIR 1.5" FASTPIPE Aluminum Compressed AIR TUBING Master KIT - HIGH CFM Flow Rate, 235-FT. KIT with 5 AIR OUTLETS (1.5" Master KIT 235FT) - Amazon.com

How to measure airflow in PVC piping requires careful measuring of airflow with a pitot tube or calibrtated anenometer to determine CFM

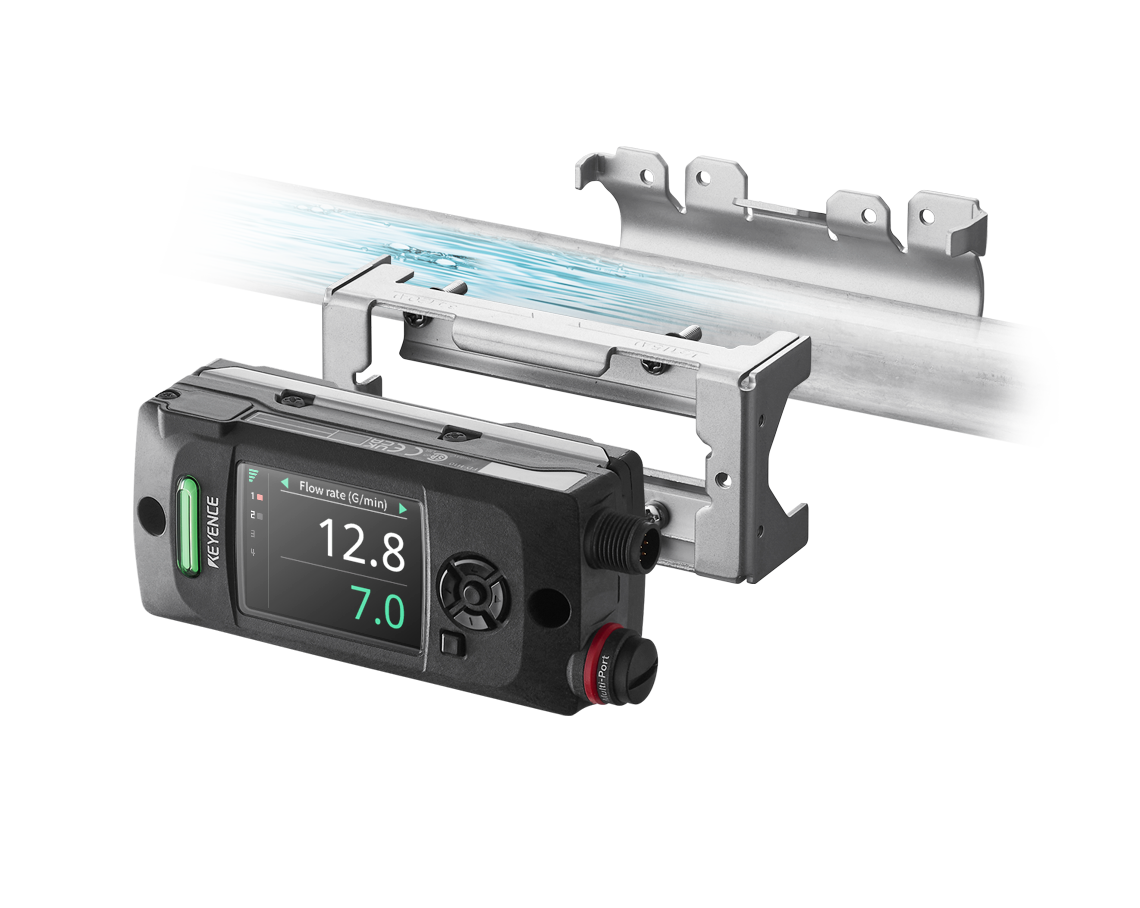

Unit Conversion Tool Air flow rate and effective cross-sectional area calculator | PISCO PNEUMATIC EQUIPMENT

How to measure airflow in PVC piping requires careful measuring of airflow with a pitot tube or calibrtated anenometer to determine CFM

How to measure airflow in PVC piping requires careful measuring of airflow with a pitot tube or calibrtated anenometer to determine CFM